Software AG’s Vice President for Strategic Programmes, Philip Hooker, tells Digital Bulletin why enterprises are increasingly leveraging the capabilities of digital twins

Could you introduce yourself and your role Software AG?

As the Vice President for Strategic Programmes at Software AG, I lead a range of structured and ad hoc initiatives at the company to accelerate the corporate exploitation of cloud.

I have over 25 years’ experience working on numerous strategic, business development and transformation programmes, and have been working with CXOs at the likes of Orange, Barclays and Nokia throughout this period I was the instigator of one of the innovation initiatives inside Nokia which became Cumulocity GmbH in 2010 until being acquired by Software AG in 2017.

What are digital twins and why are they important?

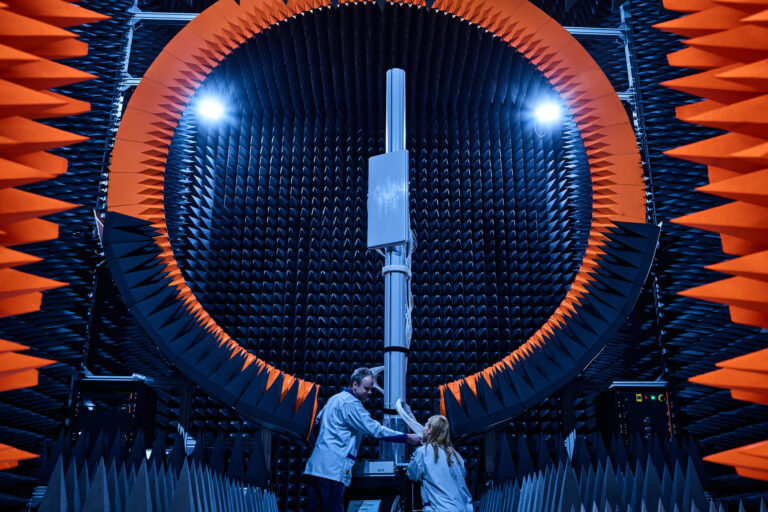

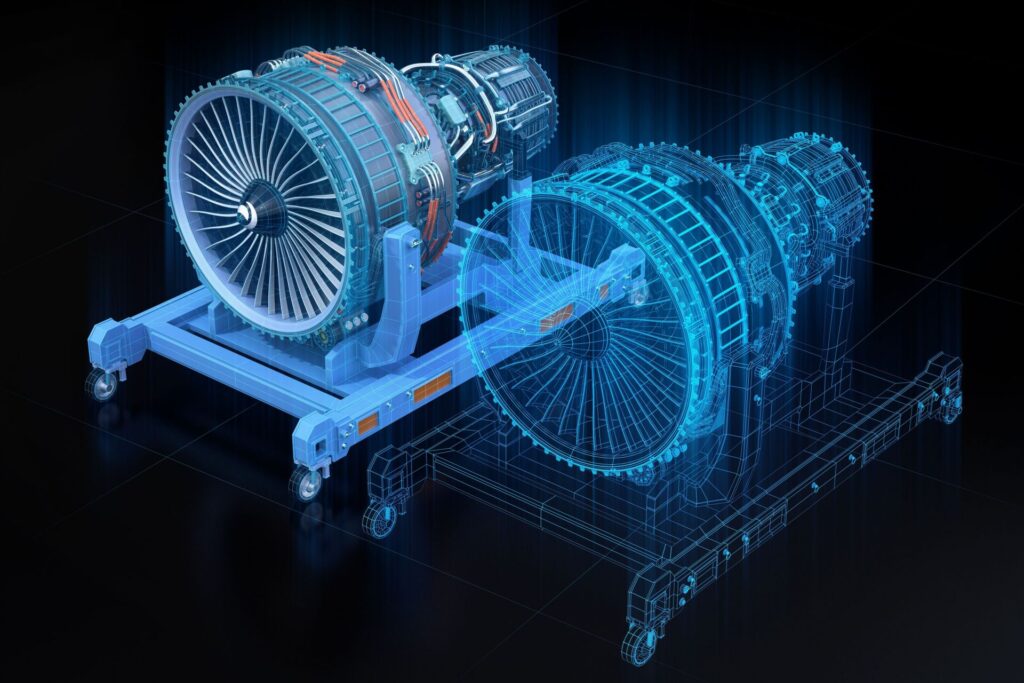

A digital twin is a digital representation of a real-world system. It can be a representation of a product, structure, facility, living being, or system. The concept of a digital twin has been inherent in software design from the outset, representing external resources such as screens, printers and human machine devices. The changes over the recent years have been related to the collective understanding of the required sophistication of these software representations and the various ways we want to interact with them. The digital twin itself acts as a single-source of truth, comprised of various components such as master data, visualisation data, life data, forecasting models, and many more.

Could you speak about Software AG’s ARIS technology and how it can help enterprises with digital twins?

Digital twins are being introduced across all lines of business as an “Enterprise digital twin” — one that illustrates your business operating model from end-to-end. Many organisations are using it to coordinate the critical interdependencies between people, processes and IT within complex digital business transformations.

ARIS is uniquely positioned to help businesses create an Enterprise digital twin to accelerate their path to digital transformation and put a magnified view on business operating models. Software AG’s ARIS process management software is closely integrated within the Cumulocity IoT platform to provide sophisticated process analysis and modelling capabilities, facilitating the task of designing-in digital twin capabilities and driving value as part of the digital transformation journey.

Similarly, Software AG’s Alfabet supports portfolio management activities relating to the provisioning of digital twins across processes and their underlying IT/OT landscapes.

What sort of technology platforms do digital twins typically operate on?

Digital twins can represent both micro and macro environments, with the latter being much more commonplace. With the macro environment digital twin, multiple heterogeneous entities can co-exist, whether it’s stages in a production line or vehicles on a highway.

A representation of a digital twin typically requires the consolidation of data across multiple systems into a single view which can be interacted with. For example, customers like Siemens use Software AG’s WebMethods Integration technologies to provide consolidation and aggregation of the data from multiple heterogeneous systems into a single view.

Which industry sectors have been quickest to embrace digital twins?

There are two notable examples of enterprises with explicit strategies to leverage technology and lead the exploitation of digital twins. Those enterprises which strategically leverage technology for the design of new products (like industrial robotic paint station manufacturers Durr), and those that do the same for the efficient delivery of services (like water utilities provider Thames Water). Both of these enterprise types exploit the digital twin to perform scenario analysis to speed the identification of insights and proactively create solutions for possible future events.

How can a digital twin help companies better carry out a technology or digital transformation?

A digital transformation requires an enterprise to consider the entirety of what it currently is, determine what it wants to be and a series of transformation steps of getting there. Typical transformation initiatives consider change in the domains of processes, organisation, technology and information.

A digital twin of the current state of an organisation allows the transformation team to easily identify areas of immediate improvement, experiment with transformation options prior to implementation and monitor the operation of those changes against a forecast, making refinements as needed.

Can you talk about the close relationship between IoT and digital twins and whether there is any crossover?

Digital twins can resample IoT devices, allowing for the management of the devices to be performed in different ways. This includes intermittent communications, historical data interrogation, future state prediction, full device management, among others. On a higher level of complexity, larger real-life assets, processes or facilities need to be virtualised on the business’s demand. Here, besides the IoT data and IoT devices, contextual knowledge of the assets is necessary. Through cross-referencing insights, forecasts and complex operations on the real-life asset can be performed.

Data for digital twins of products is often spread across several domains, IoT included. Ease of integration across these pre-existing domains and systems and the digital twins of Cumulocity IoT platform is essential – and provided by Software AG.

In addition, businesses require their capabilities to be extended with analytical models for real-time and predictive analytics of the status and behaviour of their real-life assets. Here, streaming analytics and predictive model execution engines come into play, allowing for the real-time execution of analytics and machine learning models on incoming data streams.

Compliance is a burning issue for enterprise, can digital twins be used to better oversee compliance issues?

Business is complex and regulations are rigorous, too much risk is bad for business and too much governance is just as problematic. Risk & Compliance digital twins can be created to strike a balance between control and business performance. This can be achieved by establishing appropriate controls and acceptable levels of risk, Identifying, documenting and evaluating risks, and defining measures to minimise risks and simplify audits.

Here, digital twins bring full control of overall processes, compliance and risks by addressing all risk and compliance activities, quickly initiating improvements and controlling risk assessments and audit execution.

How do you see digital twins developing and improving over the next three to five years?

The adoption of digital twin capabilities is set to grow significantly over the coming years. Managing their rollout will be an important requirement in IIoT deployments. Digital transformation will mandate business process changes and the demands of onboarding/managing fast-growing portfolios of IT & OT assets could stretch existing business functions.

Over the next five years, the importance of digital twins will rise enormously since they will be an internal enabler for additional services and an external enabler for product sales. As customer digitalisation progresses, they will want physical assets to be accompanied by the digital twin for internal documentation requirements. At some stage, the delivery of digital twins as the product documentation will be a mandatory requirement.

Virtual planning capabilities will be a key driver for this change – digital factories with systems based on digital twins will need to go beyond Manufacturing Execution Systems. The digital factory twin will allow for replanning/rescheduling and the extension of production processes, based on process simulation and the deployment of the virtually optimised processes, going beyond monitoring and prediction. Here, data from the shop floor will be relevant, but also dynamic staffing of field teams and integration of the supply chain compulsory. Therefore, information from the business layers, like ERP systems, will be needed on the plane floor to create optimised shift plans that incorporate the current status of the factory in a holistic manner.

Considerable improvements in efficiency are likely to be gained through the adoption of predictive models based on digital twins. However, the machine learning models themselves will need continuous refinement as the underlying data sources will be increasingly influenced by the processes that create them, being directly related to AI models rather than human behaviour.

What are some of Software AG’s goals in this area over the same timeframe?

In the same timeframe, our priority is to ensure Software AG is best prepared to satisfy the evolving requirements of our customers. Driven by the demand for self-service advanced analytics for process engineers, one of our key focuses involves adapting visualisation capabilities to cover other verticals like discrete manufacturing. This will improve digital twin approaches for process engineers, helping them identify the ‘golden fingerprint’ for the perfect production and synthesise the related data model in downstream systems.

Making the data insights from the digital twin available at the ‘point of use’ in an appropriate form that provides the relevant context is another key focus. For example, this could be the physics of the related components of industrial air compressors. For human operators, it could also be an AR representation of a mixed measured, simulated and predicted model of the asset. Ultimately, with the capabilities of digital twins always growing, we want to ensure that our customers can drive success as their use becomes more widespread across other industries.