Digital transformation, data analytics and automation are revolutionising every sector, and the grocery market is no exception.

The UK groceries market is worth £200 billion annually. And while giants such as Tesco and Sainsbury’s dominate it, the COVID-19 pandemic has allowed other food delivery businesses to thrive, particularly those that have been able to leverage data intelligence capabilities to their advantage.

Gousto is one of the first companies in the food industry to implement new technologies throughout its product management line, from the factories in which its recipe boxes are put together to its website and customer service channels.

The development of these technologies has allowed Gousto to become one of the latest technology unicorns in the UK, after recently raising £25 million from Perwyn and BGF in a funding round. The pandemic has undoubtedly underpinned this success, as Gousto doubled its monthly meal deliveries from 2.5 million to five million over the first lockdown, a figure that is expected to grow further as subsequent measures are taken.

However, according to Gousto’s Chief Technology Officer, Shaun Pearce, the key to the company’s success rests on its utilisation of artificial intelligence (AI) and data analytics.

“Sourcing and delivering fresh, perishable food is very difficult to do in a cost-effective way,” Pearce explains. “If you want to provide that kind of convenience to a customer at a price point that works, you have to leverage data technologies.”

This use of AI is present from the customer’s first interaction with Gousto, through the first recipe box recommendation engine, the “Spotify for Food”, which recommends menus and recipes. Moreover, Gousto’s AI also recommends recipes to the company’s chefs based on client preferences and helps them design weekly menus.

Although these technologies have already been used in ecommerce, those findings cannot always be successfully extrapolated to the groceries market.

“What we found is that selling recipes is very different from selling other things like t-shirts. It’s such an emotional product. You often have a customer not buying just for themselves but for their whole family. And so it wasn’t possible to just take one of these standard techniques and use it; what we had to do is combine several of those techniques and configure them in a way that gave us the best results.”

However, the company’s deployment of AI goes far beyond that recommendation service.

“Within our supply chain, we use algorithms to define the best possible layout for our warehouse and decide where we put carrots this week versus next week,” Pearce explains. “These are decisions that historically would have been made by humans. But, using the data we have, we can process kind of billions of different combinations of these layouts and pick the one that we think is best.”

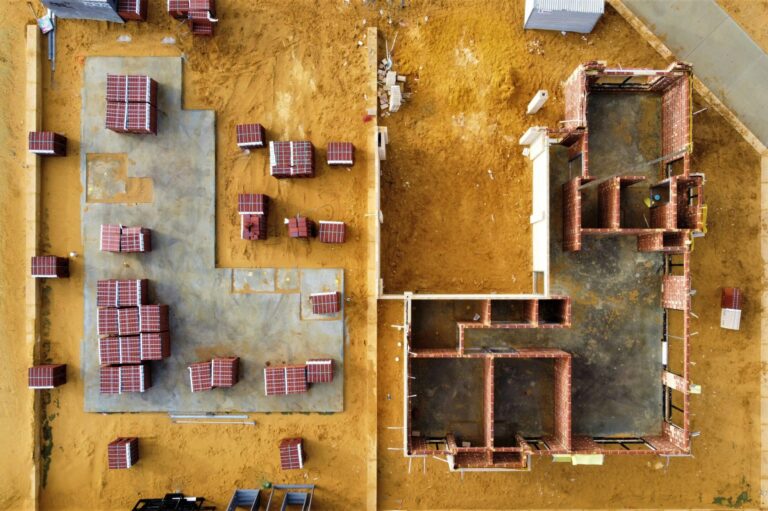

Moreover, Gousto has also automated its factories and used AI to increase its efficiency. One of the areas where this can be seen is in the automated pick lines that move the company’s recipe boxes from one station to the next, lowering congestion.

“Essentially we’ve written a SATNAV for our recipe boxes,” Pearce says. “And that’s ultimately helping us lower our costs so that we can pass those costs reductions on to customers.”

Nonetheless, the technology that has provided the most value to Gousto has been the automation of decisions, which has increased the company’s throughput by 80%. “The way that we look at AI is essentially about using the data that we have to gain insights and then automate the decision making across the business,” Pearce says.

But a transformation of this magnitude always comes with challenges, and the deployment of data analytics is no exception. Pearce identifies three main issues: data quantity, data quality and talent acquisition.

“To utilise AI properly, you need large quantities of really high-quality data,” he says. And, although Gousto’s is obtaining increasing amounts of data thanks to its rapid growth, Pearce also underlines the need to ensure its quality.

“Having large amounts of bad quality data means that you will make bad decisions based on that data,” he explains. “So the other thing that we’ve worked very hard on over the last eight years is data quality. Making sure that we can trust the data is key.”

However, data isn’t everything: talent matters too. “The most important things are people and talent,” Pearce stresses. “What we have done is build an exceptional data science team that understands the challenges of our customers at Gousto and can build these products in the right way. I think if you’ve got the people and you’ve got the data then you’ll build great AI.”

Having large amounts of bad quality data means that you will make bad decisions based on that data. Making sure that we can trust the data is key

Nonetheless, the automation of Gousto’s production line faces additional challenges which are unique to its industry: the management of perishable items. For this reason, the company is currently working on R&D projects that will use robots to pick fresh perishable food without damaging it.

But the goal is not only to not damage food; it’s also to not waste it.

If food waste was a country, it would be the third-highest emitter of greenhouse gases after the U.S. and China, according to the United Nations’ Food and Agriculture Organization. “Focusing on that as a problem for the environment is extremely important to us,” Pearce explains.

Gousto has an advantage over traditional grocery stores in that its model naturally reduces food waste for clients, as they only receive the exact ingredients in the exact quantities they need to make each recipe. In addition, the company has recently reduced its use of plastic packaging by 50%. However, Pearce does not think this is enough.

“We can only really stand by that if we lower food waste within our supply chain as well,” he says. “We have used AI and algorithms to do both short-term, medium-term and long-term forecasting; What that allows us to do is to confidently order just enough product from our suppliers and make sure that we lower the amount of waste of our food chain to very low single-digit percentages, which is a fraction of what the supermarket industry would be creating at any point in time.”

However, the technological challenges only increase as a company grows, and Gousto is no exception. After having recently reached a valuation of £1 billion, the company is on its way to open three fulfilment centres in the UK over 2021 and hiring 1,000 new employees.

“As you grow, data, in general, becomes more and more important,” Pearce points out. “The value of the decisions you’re making is higher and there’s a tendency to want to use data more and more in the making of those decisions, from strategic ones all the way down to the decisions we make on a minute-by-minute basis in the warehouse.”

During this process of scaling-up, Pearce’s team realised that the timeliness of the data they had – updated every four hours – was not good enough. “If we made a decision based on data that was four hours old, potentially we weren’t making the optimal decision,” he says.

For this reason, Pearce’s work over the last year has been focused on improving the data pipelines to be able to provide real-time data to every team across the business, which is now able to make fine-tuning adjustments throughout the day to optimise the supply chain.

“That real-time data informs our algorithms to help us make the best possible decisions,” he says. “But it also informs humans. Humans are a really important part of this, and they will forever be. Our leaders and our managers on the ground in our factories understand how the teams are operating, how the systems are operating, and the data empowers them to make the right decisions as quickly as possible”.

Gousto’s interest in the human part of their business is also translated to the needs of the whole country, particularly during COVID-19. During the first lockdown, Gousto worked with charities such as Shelter and the Trussell Trust to provide over 8,000 meals to those in need and prioritised deliveries to vulnerable clients and NHS workers. During this second lockdown, Gousto has continued to do the same.

“We want to make sure that we’re supporting people that are most in need, both our customers and the wider UK population,” Pearce says.

Moreover, as people get more and more used to working from home, they also keep up with the habit of ordering recipe boxes, and Pearce does not see this trend dying down anytime soon.

“We believe the recipe box industry as a whole has a lot of space for growth,” he says. “I think customers will continue to adopt online grocery as a whole. And for us, it’s all about choice and convenience. I think that if we keep on listening to customers, we’ve got a huge amount of space to grow within the next five years.”