Numerous sole proprietors and small business owners rely heavily on the manufacturing sector. Modern technological advances have resulted in the development of multiple feasible new approaches to mass production on both the micro and macro scale.

Three-dimensional (3D) printing is one such method, and it has seen increasing adoption in the manufacturing sector in recent years. Currently valued at $12.6 billion, the market is forecasted to grow to $37.2 billion by 2026. A significant number of businesses incorporating 3D printing into their production processes is growing.

This article was created to show you and your team the benefits of including 3D printing into your processes. However, before the benefits, here’s a discussion on the process of 3D printing to understand how it truly works.

What is 3D Printing?

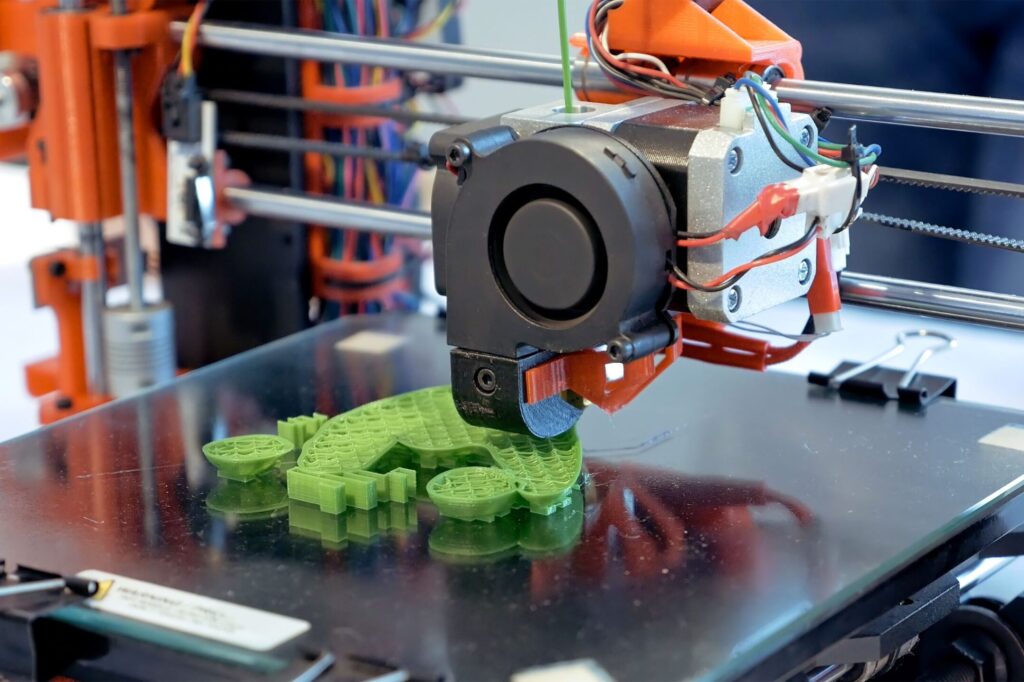

Using a layer-based technique, 3D printing technology takes cues from a computer software. Additive manufacturing is a process that uses layering to create objects of varying shapes, sizes, colors, and complexity. These layers can be made of anything from composites to other materials like plastics.

Traditional inkjet and 3D printers take similar principles but in 3 dimensions. It enables the creation of 3D objects from scratch by combining precise instruments and sophisticated software. This printing process is also well-suited to rapidly developing complex, custom objects.

The benefits of 3D printing

While factories use various machines, tools, and equipment to transform raw materials into completed goods, 3D printers have several distinct advantages even as 3D printing’s future isn’t certain.

1. Faster product development

Because 3D printers are used in the manufacturing industry, prototypes for new items can be designed and made quickly. To begin mass production, a manufacturer must first create a prototype. Fortunately, quick prototyping is possible with Selective Laser Sintering (SLS) 3D printing.

If you want to learn more about the intricacies of SLS 3D printing, then consider visiting sites like sculpteo.com. Moreover, companies in the manufacturing sector have the resources to rapidly design and fabricate prototypes of new items because they’re taking advantage of 3D printing.

2. Alleviates overhead expenses

One of the significant benefits of 3D printing technology is that it requires less labor, which reduces costs. The cost of labor significantly impacts determining the budget for developing a framework. Labor expenses are high in traditional manufacturing because skilled machine operators are needed. But with 3D printers, the operator only needs to click one button to start the fully automated process. Furthermore, making items with 3D printing is the same as making them in small and large quantities.

3. More precise and high-quality

For designers, the most considerable challenge is figuring out how to mass-produce their creations in the most efficient way feasible. Additive manufacturing equipment completes the task in a single, built-in stage. The build step of this process is so easy to follow that there’s no need for a machine operator. Once the computer-aided design (CAD) program is finished and sent to the machine, the process takes only a few hours to complete. The device gives the designer greater freedom in developing the final product because there aren’t as many roadblocks when tinkering with the design.

4. Ability to produce complex and unique parts

Traditional manufacturing methods use cutting tools and molds to create the final products. Therefore, it was challenging and time-consuming for designers to create complex shapes using this technique. The advent of 3D printing offers a solution to this problem. Provided that suitable materials are available, it can give the expected outcomes.

5. Greatly reduces financial risk

Manufacturing hazards can be reduced with the use of 3D printing for enterprises. The emergence of 3D printing technology has made it possible for designers to test their work on physical prototypes before investing heavily in potentially disastrous mass production.

6. Retains a high volume of production

A high-volume 3D printer is the best option for any large-scale manufacturing operation that needs to keep up with demand. Hundreds, if not thousands, of components can be made in a single day using this equipment. It’s invaluable if you mass-produce standard components, products, or tools. Because they can print many things quickly, these printers are great for factories that make many different things in large quantities.

Moreover, engineers can produce even tiny components in vast quantities. It’s helpful to mass-produce 10, 25, or 50 replacements of a tricky component. Engineers can employ high-volume printers to mass-produce small tools and supplies. It provides a great deal of leeway for both large and small companies.

Takeaway

With the effects of 3D printing, manufacturing stands head and shoulders above the rest. Undoubtedly, 3D printing has a broader range of benefits than conventional production. Incorporating 3D printing into production would be helpful, of course, with the right expertise and equipment.